So I have been filling a couple hours a day with an engine stand adapter project so that I can work on it easier. The worktop I have is designed for woodworking projects, so the table is pretty tall trying to work on the top of the engine.

I took a crapload of pictures in case someone wants to do this on the cheap. Other than the welding wire, I have a grand total of 25$ in parts (I scrounged some) I would have done a few things differenly if I had more scrap steel around to work with as well.

So, this is what I started with:

This is the 25$, which consisted of 2 - 1.25" EMT 90 degree elbows, and a 8ft length of 1.5" frost fence post. All of it is galvanized, so everywhere that i did any welding, it was ground off.

I used this occasion to try out my $25 horezontal bandsaw that I picked up from a school auto shop that just wanted to get it out. Worked OK considering the blade was VERY dull, so I went really slow. It was way too slow, and I knew it would be, so I threw the metal blades in the sawzall.

I then cut a short section of the pipe, then split it

Using a vice, I flattened it out:

I had a short scrap piece of plate, which was the perfect width, so I ended up clamping it in, then hammering the flattened pipe end around it so that it was held tight.

Then I took metal sheet, fitted it, and welded it up to the open section of the pipe:

Here it is in place.... needs a bit of trimming:

End trimmed, elbow slipped into place for illustration, this is what I was originally intending:

Nut welded on to provide a bit of spacing. After this was welded on I took it to my shop and drilled through both with a drill press.

Motor mount elbow trimmed so that there is the proper clearance from the block:

This is one of those areas I would change. I didn't have any more plate around, and be damned if I could find anything around. So two pieces of angle... not the prettiest. I will likely change it after the motor is finished with it's rebuild:

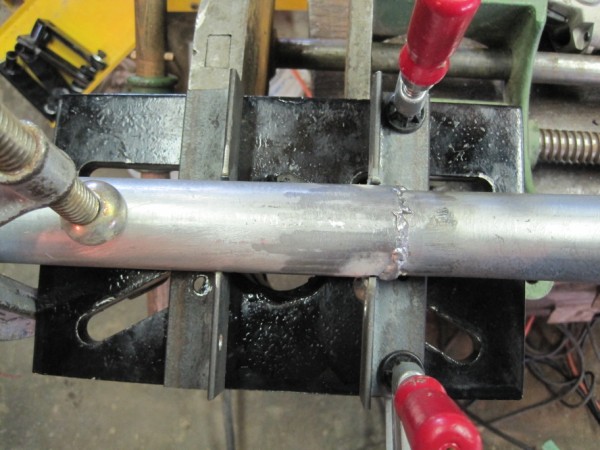

I ditched the 2nd elbow, because it would have offset it to far off of the engine stand. So the piece that attaches to the rear plate got notched and tacked:

Fully welded:

:

: