Page 1 of 6

C900 gearbox girdle

Posted: Tue Aug 23, 2016 11:56 pm

by squaab99t

New project time.

Scanwest is building me a high pro gearbox. Shot peen and cryo treated gears. Rob Walden touch and his little goodies he adds to make it handle more power and last longer.

I took some pics of the gears' post treatment.

A special roller bearing he had made up for the gear shaft.

A sport and rally LSD that was on the bench going into Rob's car. If only it could speak.

My Quaife is lurking in the background.

Enough of the Saab car porn.

I'm going to see if I can design and build a girdle for the back of the gearbox. Something bolt on and does not affect the ring pinion backlash.

I'll start off in cad but at the end of the day I'll use a mockup to see the final configuration.

I have a spare 5 speed box and I built a new fixture that fits the Park bike stand I used on my header project.

Similar to the factory gearbox hanging fixture.

Re: C900 gearbox girdle

Posted: Wed Aug 24, 2016 12:00 am

by squaab99t

Fixture continue.

Spinner, for access on the mockup and eventually fabricating the assembly.

Re: C900 gearbox girdle

Posted: Wed Aug 24, 2016 2:25 pm

by Krizzie

This is going to be good!

Re: C900 gearbox girdle

Posted: Wed Aug 24, 2016 6:32 pm

by hutch

Very excited to see what sort of product you come up with!

So I've always been curious about this, and I have zero engineering knowledge to back it up, but whats the scientific reasoning behind bracing the gearbox either through the steel diff cover or the girdle like this? Or I guess put another way, what sort of failures will this prevent?

It seems to me there are cluster failures from just sheer high torque, synchro failures from abuse, pinion bearing breakdown, and I'm sure Jeff has invented a few other ones

Is the thought that a lot of these are a result of movement of the case causing the tolerances to go out of spec? Is it possible that too much bracing could just transfer power to other, weaker pieces? I'm really not sure what point I'm trying to make here, just curious how much 'give' is good for the system vs. the need to brace things to keep the parts lined up properly.

Re: C900 gearbox girdle

Posted: Thu Aug 25, 2016 3:02 pm

by squaab99t

Hutch, for not being the engineering type, that is a pretty good shot in the dark.

Mesh gears in general want to spread apart axial wise when torsional loads are going thru them. Think of them as your finger on your hands. Tightly meshed, more contact, the base of the finger is fatter and less flex. Now pull your wrist apart to simulate the axis loading and your fingers barely engage, less contact, the tooth see more stress over a smaller cross section area of the tooth itself. Now again there can be too much of a good thing where the tooth engagement is so much it eats itself up due to no room for film lubricant or just geometry of the profile and it binds.

The girdle's job will be to minimize the case deflection right hand side as that is the side the reaction forces want to go due to the gears' config. The girdle as going to act like an anatomical splint and will sympathetically load share on the left hand side.

You are right the load has to go somewhere. The change will chase the load to another area of the gearbox. The hope is that part of the box can handle the amount of Hp the engine puts out. The aft end rhs seems to be the failure point of the case. It might be from where the shifter shaft enters the case. It is pretty thin. Got to remember the gear box was originally designed for 100 Hp.

Re: C900 gearbox girdle

Posted: Thu Aug 25, 2016 4:20 pm

by Geoff

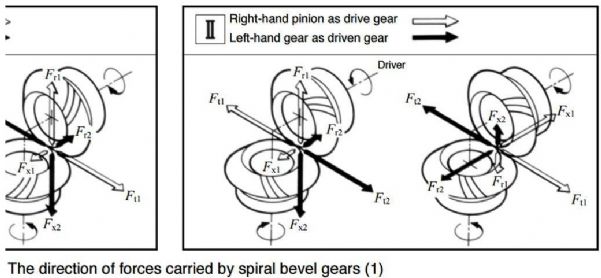

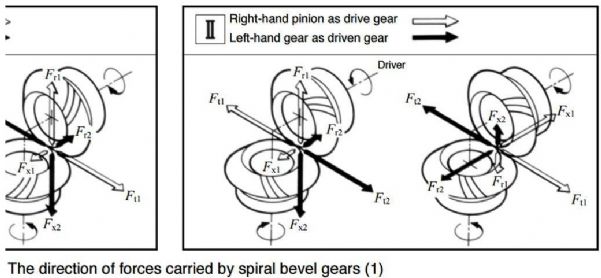

Force vectors

You can imagine the gear labeled "Driver" to be your pinion gear and the other as your ring gear. Fx2 is the force pushing the ring gear out of the side of the transmission. The gearbox girdle should help prevent that from happening. But as you and Dennis both mentioned, the force has to go somewhere. So while the diff may not exit the side of the transmission case, the force will be exerted on the case/girdle and the gear teeth will be loaded more as well. Keep in mind there is a resultant force (Fr1) which is acting on the pinion and is loading the pinion bearing.

Re: C900 gearbox girdle

Posted: Thu Aug 25, 2016 7:40 pm

by hutch

Ha well out of high school I did a year as an engineering major before switching, but it was all intro level courses so I never got to the good stuff. Though the resultant force did give me horrible flashbacks to Statics class

Thank you both for the very in depth explanation, as I said I'm looking forward to seeing the process...

Re: C900 gearbox girdle

Posted: Thu Aug 25, 2016 10:19 pm

by squaab99t

Yes, Geoff's diagram gave me flashbacks too. 30 years ago I took machine design and dynamics. Have not seen those in a while.

I too look forward to the process.

For now some eye candy with a coat of black paint.

Re: C900 gearbox girdle

Posted: Fri Aug 26, 2016 2:30 am

by KoogiA17

Glad to see you are undertaking another wacky project Dennis!

Those diagrams gave me flashbacks as well! Did 2 years of tribology and mechanical transmissions on the 3rd and 4th Year at Uni.

Good luck with this one and your ability to find a further use for a Park bike stand is impressive.

Re: C900 gearbox girdle

Posted: Sat Aug 27, 2016 4:29 pm

by squaab99t

Always thinking about the next step..

The stand is an example on how to have a base and make specific tools that interface. Saves on shop real estate and fab time. Don't think it up to the task of an engine. Maybe some tension cable to react the loads? Think cranes.

Re: C900 gearbox girdle

Posted: Fri Nov 25, 2016 7:22 pm

by Jon1

Dennis, any updates on this?

Re: C900 gearbox girdle

Posted: Sat Nov 26, 2016 12:47 pm

by squaab99t

Jon1 wrote:Dennis, any updates on this?

This question is rather ironic. Almost two years ago you asked about the header and turbo. We all saw what that lead to.

Maybe over the holiday break I'll bust out the cardboard?

Re: C900 gearbox girdle

Posted: Sat Nov 26, 2016 2:25 pm

by vintagesaabs

Dennis, Are all the spare parts in your shop as shiny sanitary as this spare trans case ?

I'm not sure I could even get a used trans this clean.

It's a pleasure to view your process.

Re: C900 gearbox girdle

Posted: Sat Nov 26, 2016 3:30 pm

by squaab99t

vintagesaabs wrote:Dennis, Are all the spare parts in your shop as shiny sanitary as this spare trans case ?

I'm not sure I could even get a used trans this clean.

It's a pleasure to view your process.

What can I say? It's a hobby, don't have to make money at it.

Re: C900 gearbox girdle

Posted: Sat Nov 26, 2016 6:09 pm

by Jon1

squaab99t wrote:Jon1 wrote:Dennis, any updates on this?

This question is rather ironic. Almost two years ago you asked about the header and turbo. We all saw what that lead to.

Maybe over the holiday break I'll bust out the cardboard?

Well, if it takes 17 months for this project and it turns out as nice as the header and turbo, so be it. Take your time and do it right, like I needed to say that.