Page 3 of 6

Re: C900 gearbox girdle

Posted: Wed Dec 14, 2016 5:07 pm

by Jon1

Crazyswede wrote:I have no need for one. I can understand the need to protect your investment in a pricey gearbox build though.

Does that mean I can have the transmission that came out of your 86 notchback rally car?

Re: C900 gearbox girdle

Posted: Wed Dec 14, 2016 7:33 pm

by KPAero

I had a 5 speed fail in that area on my car. The case and right side inner driver were cracked and the driver pushed out .5". Probably not what most would consider a high HP car either, with maybe 200hp? for the time that box was in. However, the car gets a good share of abuse, and the box had 150,000 miles before I got it. R&P and gears all mostly intact for what it's worth.

I've considered doing something similar for the 4 speed.

Re: C900 gearbox girdle

Posted: Wed Dec 14, 2016 11:47 pm

by squaab99t

Crazyswede wrote:I have never seen this area fail. I recall seeing a picture at some point in time but have never been able to find it again....of a blown apart diff housing. Other than the neato factor I have no need for one. I can understand the need to protect your investment in a pricey gearbox build though.

This ring a bell?

viewtopic.php?f=7&t=4131&p=44908#p44908Hard to say if this was preventable.

I'm not sure I need a girdle, but if done right it certainly won't hurt. Kinda like wearing armor downhill mountain biking. You are not planning on crashing, but it is nice when you do.

Re: C900 gearbox girdle

Posted: Thu Dec 15, 2016 8:10 am

by Crazyswede

squaab99t wrote:Crazyswede wrote:I have never seen this area fail. I recall seeing a picture at some point in time but have never been able to find it again....of a blown apart diff housing. Other than the neato factor I have no need for one. I can understand the need to protect your investment in a pricey gearbox build though.

This ring a bell?

http://saabrally.com/forums/viewtopic.p ... 908#p44908Hard to say if this was preventable.

I'm not sure I need a girdle, but if done right it certainly won't hurt. Kinda like wearing armor downhill mountain biking. You are not planning on crashing, but it is nice when you do.

Yes, that looks familiar.

Re: C900 gearbox girdle

Posted: Thu Dec 15, 2016 8:11 am

by Crazyswede

Jon1 wrote:Crazyswede wrote:I have no need for one. I can understand the need to protect your investment in a pricey gearbox build though.

Does that mean I can have the transmission that came out of your 86 notchback rally car?

Comedian in every crowd.

That gearbox shouldn't need one given the relatively low torque engine sitting on top of it.

Re: C900 gearbox girdle

Posted: Fri Dec 16, 2016 8:17 pm

by Jon1

Re: C900 gearbox girdle

Posted: Fri Dec 16, 2016 8:52 pm

by squaab99t

wowzzers. You have been busy. Add some ribs to the side plate around the perimeter reaching aft and that will stiffen that plate to carry the load.

The angle picking up the diff plate has to be tight holes to carry the load. As a stress engineer explained, friction does not count. The hole has to bear up against the fastener.

Re: C900 gearbox girdle

Posted: Fri Dec 16, 2016 9:12 pm

by Jon1

I threw that together with some stuff I had available. It was just to put out ideas and is all bolt on. How do you make a clearance hole for a bolt "bear up against the fastener"? If I add dowel pins in the angle on both planes, will that work?

Re: C900 gearbox girdle

Posted: Fri Dec 16, 2016 11:03 pm

by squaab99t

Jon1 wrote:I threw that together with some stuff I had available. It was just to put out ideas and is all bolt on. How do you make a clearance hole for a bolt "bear up against the fastener"? If I add dowel pins in the angle on both planes, will that work?

I like the all bolt on concept. I'm a visual and tactile person, so I'm all about physical mockups.

How does one load a fastener in shear? Four years of college, but most importantly +25 years in aerospace, seeing it done right or on the other hand a giant cluster F.

The trick are tight holes. They have different classes of holes, 1, 2,and 3 and 1 being the tightest (smallest). The other side of the coin is how precision located are the gearbox threaded holes, and the studs or fasteners. Keep in mind the part floats and you want to have that angle's surface bear up against the driver plate. Shims may be required at this interface for good fitup and no preload.

Back to the fastener and bearing. Geometric Dimensioning and Tolerance. This will drive your requirements to a print. Now if you are doing a one off you can measure and transfer the info to a mill, pop in the holes and you are good to go. That said you maybe only use that assembly set on that gearbox and it backlash setting.

The dowel trick is interesting. One could bolt the thing together with class 3 holes and then match drill and ream the angle and the diff cover with minimum of two class 1 holes to accept dowel pins and they would carry the load. I could also see doing the same thing on the driver plate and angle.

Re: C900 gearbox girdle

Posted: Thu Dec 22, 2016 8:13 pm

by DrewP

Just spooge a bunch of JB Weld all over the plates and the case!*

*=Do not do this.

Re: C900 gearbox girdle

Posted: Fri Dec 23, 2016 10:04 pm

by squaab99t

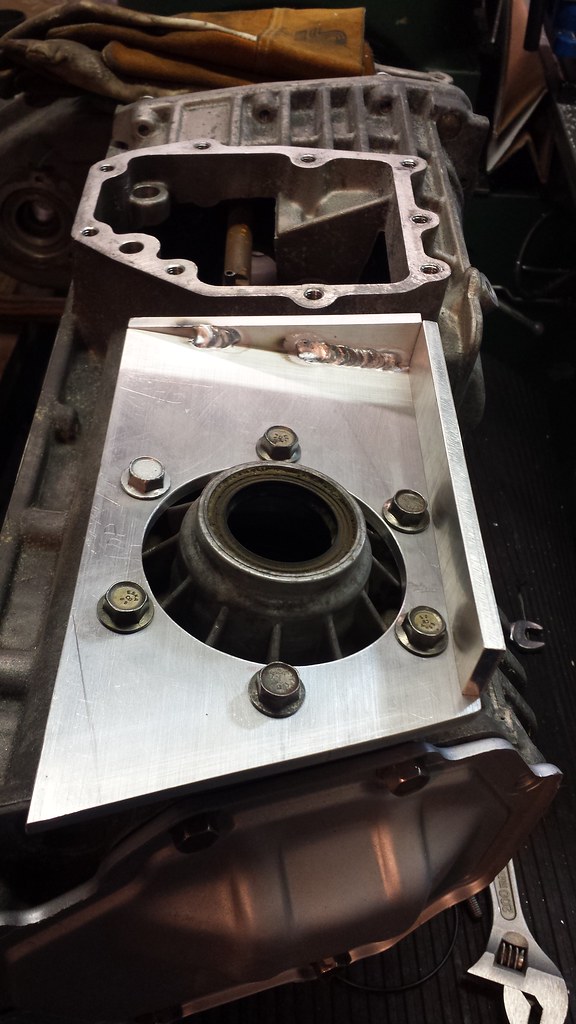

Holiday break started today, so it was time to have some fun with mockup.

Augmented the diff cover with load path carrying members. I'll add the right side driver plate and tie back into the righthand collars with two more ribs.

Re: C900 gearbox girdle

Posted: Sat Dec 24, 2016 12:42 am

by squaab99t

On to the business end...

The driver assembly is shaping up.

Added a web between the two frames. Almost creates a complete box section. In this case they call it a bathtub.

Re: C900 gearbox girdle

Posted: Sat Dec 24, 2016 10:34 am

by gmreider

Dennis ,I like that a lot. Gonna be hard to put the shift pin in place though.

I 'll post some pictures of our Lemons car failure at the lower chain drive end.

Re: C900 gearbox girdle

Posted: Sat Dec 24, 2016 3:09 pm

by squaab99t

gmreider wrote:Dennis ,I like that a lot. Gonna be hard to put the shift pin in place though.

I 'll post some pictures of our Lemons car failure at the lower chain drive end.

Thanks Gary for the feedback. That is the nice thing about the cardboard, not too much invested and you get some pretty good validation. Also the card stock being flimsy give a good indication where a little material placed in the correct location stiffens things right up.

Maybe install the shift coupler prior to the girdle? The pinch bolt on the shifter side can be reached from the top using every extension I own. I have always used the U joint version or the rubber cylinder, and not the double T bone.

Happy Holidays everyone.

Re: C900 gearbox girdle

Posted: Mon Dec 26, 2016 6:05 pm

by gmreider

Dennis here are some shots of the latest failure. The lower primary chain bearing housing in a 5 speed. From our # 113 Lemons car. I have not seen this before and I have seen the insides of many transmissions.