Page 4 of 6

Re: C900 gearbox girdle

Posted: Tue Dec 27, 2016 7:56 am

by Geoff

Nice mockups! This is one of those projects that bounce around my head from time to time. The base geometries, many bolt holes, lack of published dimensions, adjustability needed at the diff carrier, and ability to fit around other parts of the car add up to an interesting challenge.

John's comment about dowel pins got me thinking about using shoulder bolts. Shoulder bolts have tight tolerances on the shoulder (similar to pins) so they could be used the way pins could be - to take the load between components - plus they would be easily removable. If you could get really precise measurements off your gear case you could potentially use shoulder bolts at some, or all, of the factory bolt locations. But as Dennis pointed out, due to manufacturing variances it might not fit a different case.

Re: C900 gearbox girdle

Posted: Sat Dec 31, 2016 1:39 am

by squaab99t

Thanks Gary for sharing the pixs. I have never seen a failure like that before.

Looks like it ran low or without lubricants. SWAG

Re: C900 gearbox girdle

Posted: Sat Dec 31, 2016 11:45 pm

by DeLorean

It most likely did not run low on lubricant. The car does have a trans cooler, but it feeds and returns into the main case. I am rolling it around in my head now and am kind of wondering. My initial thought was that, well maybe, we had tightened those 3 bolts down to friction tight, but they were not tight against the soldered bolts in the direction of force? Perhaps the housing shifted at full torque and created an impact failure that blew the whole housing apart. I know it sounds kind if far fetched. But in Racing we have broken things where numerous Saab tech's have said "Huu, never seen that one before..." Any possibility we are starving the primary drive of lube?

Re: C900 gearbox girdle

Posted: Fri Mar 24, 2017 6:35 am

by Jon1

Dennis, any updates?

Re: C900 gearbox girdle

Posted: Sat Mar 25, 2017 8:00 pm

by squaab99t

Jon1 wrote:Dennis, any updates?

Just new plates with the hole dia tightened up. I need to cad the paper dolls I made with the paper mock-up and send those to the laser cutter.

Day job and other family projects kinda puts a damper on the Saab projects.

Re: C900 gearbox girdle

Posted: Sun Jan 14, 2018 6:20 pm

by Jon1

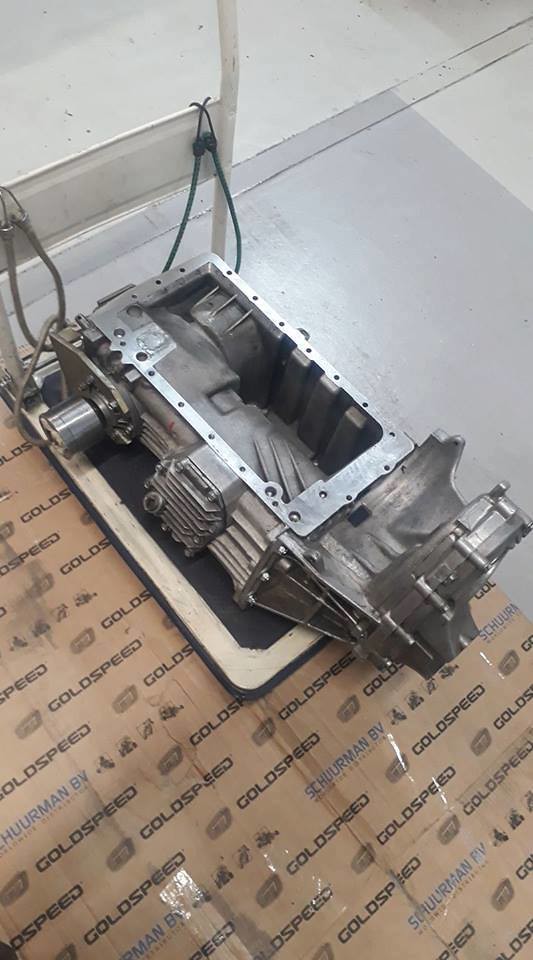

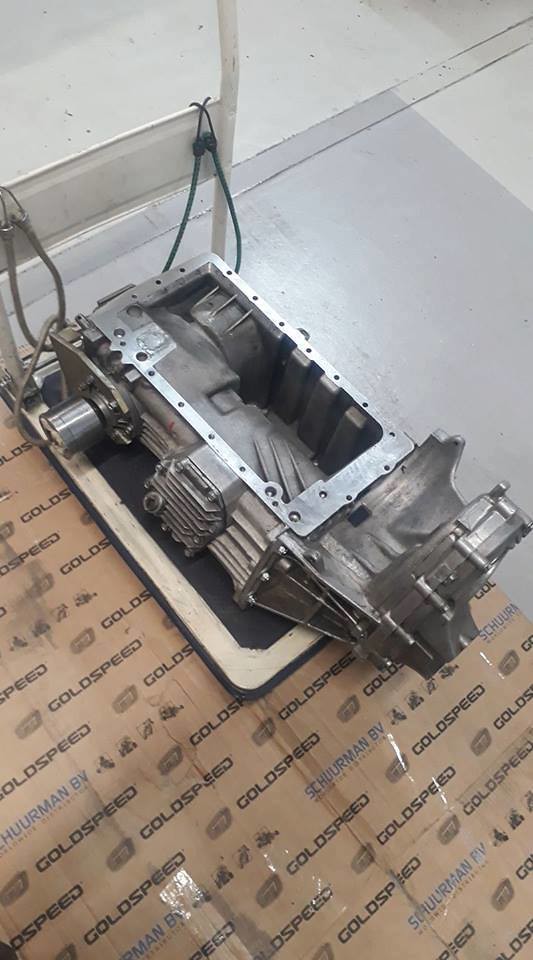

Found some more photos

Re: C900 gearbox girdle

Posted: Tue Jan 16, 2018 11:41 pm

by squaab99t

Thanks Jon. Interesting add on double plate. I’m thinking it puts those bolts on the diff cover in bending and you can’t really up the diameter more than the 8mm. May need to study it some more to help understand the design intent.

The side plate with fins makes it look like a Moto Guzzi cylinder head.

Re: C900 gearbox girdle

Posted: Sat Sep 28, 2019 1:12 am

by squaab99t

3 years later... Update time

After working on the inner driver cup sleeves I figured let’s keep it going.

Adding a strongback to my existing diff cover design. Stepped up to cutting metal to get the creative juices flowing.

Re: C900 gearbox girdle

Posted: Sun Sep 29, 2019 5:51 pm

by squaab99t

Fun in the mancave. Some whiskey, welding, and working it.

Copper chill bar on the back of the thin sheet metal keeps it nice and clean on the backside and reduces the chances of blowing thru.

Re: C900 gearbox girdle

Posted: Mon Sep 30, 2019 12:00 pm

by Geoff

A bunch of the other mechanical engineers were just hovering around my screen, "Oooh! What's that!?"

Re: C900 gearbox girdle

Posted: Mon Sep 30, 2019 7:24 pm

by squaab99t

Geoff wrote:A bunch of the other mechanical engineers were just hovering around my screen, "Oooh! What's that!?"

This made my day. Thanks.

Re: C900 gearbox girdle

Posted: Wed Oct 02, 2019 4:23 pm

by 99Super

Dennis,

As I go through the tranny for my new engine build, I got looking at the same issue.

Instead of tying the right bearing cap to the rear diff cover, what about tying it to the side cover?

Seems one could build a much less heavy support as there would be more natural resistance to the levering effect of the ring trying to push out the side in front of the bearing cap. With the rear girdle, you are trying to prevent the leverage of the ring/pinion using a shorter (albeit, much heavier) lever. By mounting the brace to the side cover, the lever is longer and more resistant to the ring/pinion. (OK you engineers, is this even close?? ; )

I'm working in Bend this week, but I'll try to mock up what I'm thinking in cardboard either this weekend when I am back in BOI, or over the week of Italian Slave Trader Day (I already have Mon and Fri off, I'm taking the rest of the week and staying in BOI) when I really have time to work on stuff.

I've got Binky mostly useable (I still need a new steering box for it), so back to Frank.

john

Re: C900 gearbox girdle

Posted: Wed Oct 02, 2019 11:39 pm

by squaab99t

John I understand what you are saying. I’ll most like use both the diff cover and the side cover. You want to make the arms/ levers as short as possible. The load from the ring and pinion will be a force in say pounds. In order to react that force you need to couple that via surface or plate and a lever arm. That said, the shorter the arm the less load into the plate.

As far as the big heavy structure, it looks heavier than it is.

A bump of 34% weight over the baseline diff cover. This equates to just under a pound increase.

Still have to build the lever and hoop to reach around 90* to pickup the inner driver. That will most like be heavier. Time to put the gearbox up on the rotary stand.

Re: C900 gearbox girdle

Posted: Sun Oct 06, 2019 12:06 am

by squaab99t

Phase 2: reach around.

Inner driver flange complete. Mockup of the webs in cardstock to get a visual and spatial representation.

Tack those in and work the side cover support next.

Re: C900 gearbox girdle

Posted: Tue Oct 08, 2019 9:10 pm

by squaab99t

No metal was harmed in the making of this mockup.

First cut.

Round 2: extended the web outboard and more to the center on the axle.

Now the trick is how to get access to the fasteners?