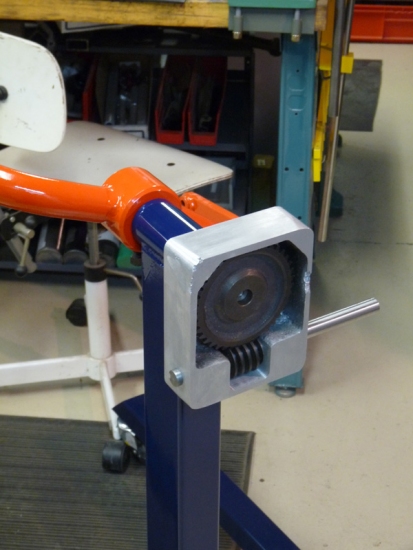

I have the nice factory service fixtures for mounting the engine, and a cheap engine stand I modded to hold the factory bracket, but it was a pretty crappy setup overall.

So i decided to build a basic but sturdy stand that worked better with the SAAB holding fixtures (I also have the transmission and cylinder head holding fixtures)

So I went to the local steel yard and picked up about $35 worth of steel and went to work.

I built a simple framework for the stand, the legs are spaced apart so that they can go around a rolling work table that I also just built - which will allow for easier tranfering of a block from a table to the stand.

Here is the rolling cart - built out of some old steel from some pallet racks and casters from an old tool box. I put a small bin shelf underneath it to hold engine components.

I also pressed bronze bushing into the pivot tube - probably overkill but it just seemed like the right thing to do.