Page 1 of 2

Rebuilding hydraulic lifters

Posted: Sat Jan 14, 2017 10:33 am

by Jon1

Has anyone here had any experience rebuilding hydraulic lifters? I don't know the history on any of the engines that came in my cars and they are 25 to 30 years old. I watched this video and I think I will attempt to disassemble and clean some lifters.

https://www.youtube.com/watch?v=ySf0r8GGMOY Another video

https://www.youtube.com/watch?v=zu60ExxQjlg

Re: Rebuilding hydraulic lifters

Posted: Sun Jan 15, 2017 10:20 am

by squaab99t

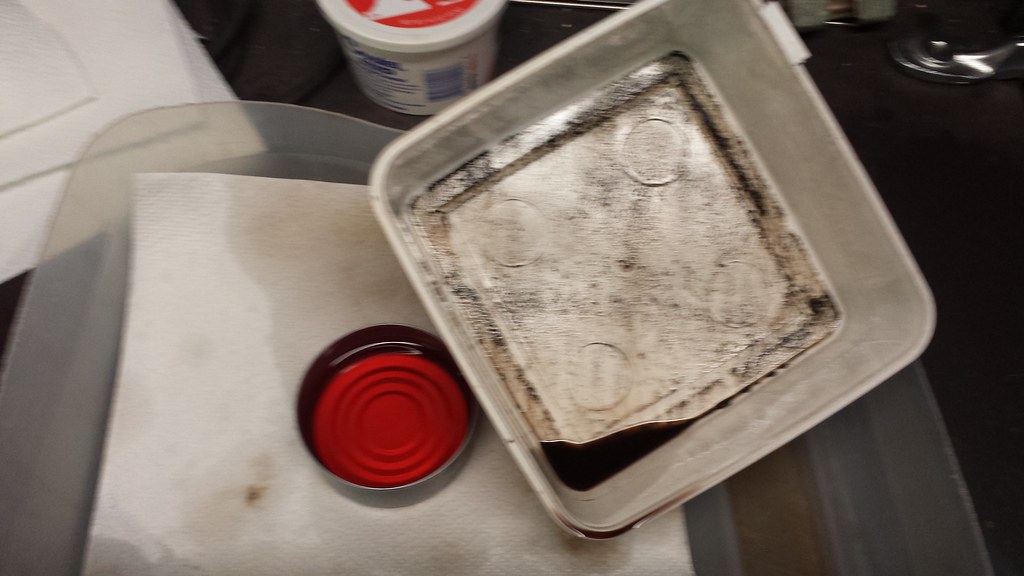

I have only went as far popping out the piston assembly and putting that in an ultrasonic bath. To be honest, I have only cleaned them, coated them with oil, and sitting in a bag.

That is a great vid on complete disassembly and reassembly. Even the same manufacturer IND.

Re: Rebuilding hydraulic lifters

Posted: Sun Jan 15, 2017 4:28 pm

by Jon1

I popped out the piston assembly, but could not get them any farther apart. I cleaned them in kerosene, pushing the check ball in and out to release the dirty oil. I cleaned them multiple times and then lubed them with oil, making sure they weren't full of oil before reassembly. Five out of the sixteen were very gummed-up before cleaning. I am glad I took the time to clean them.

Re: Rebuilding hydraulic lifters

Posted: Sun Jan 15, 2017 4:33 pm

by Jon1

Re: Rebuilding hydraulic lifters

Posted: Sun Jan 15, 2017 4:36 pm

by Jon1

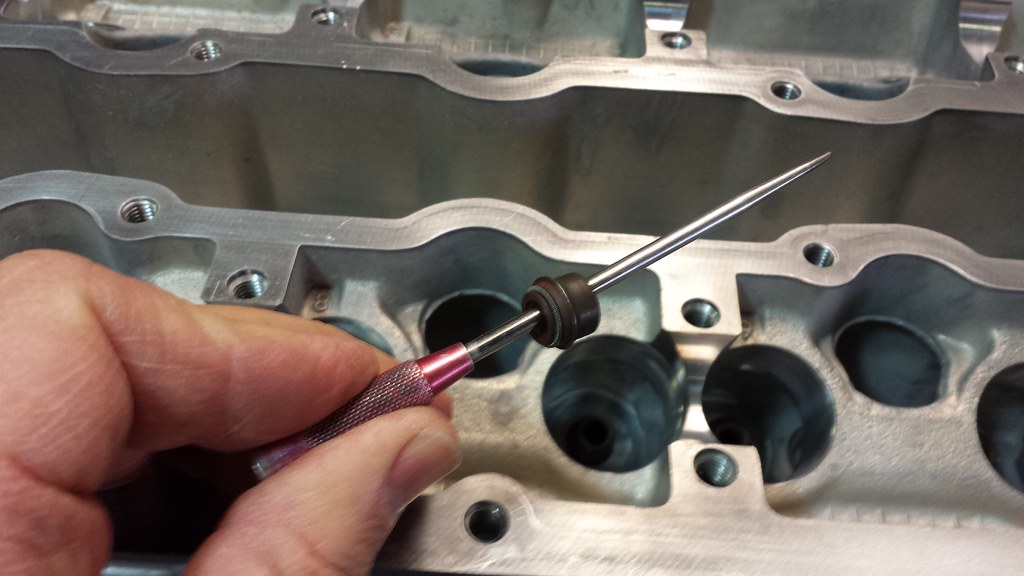

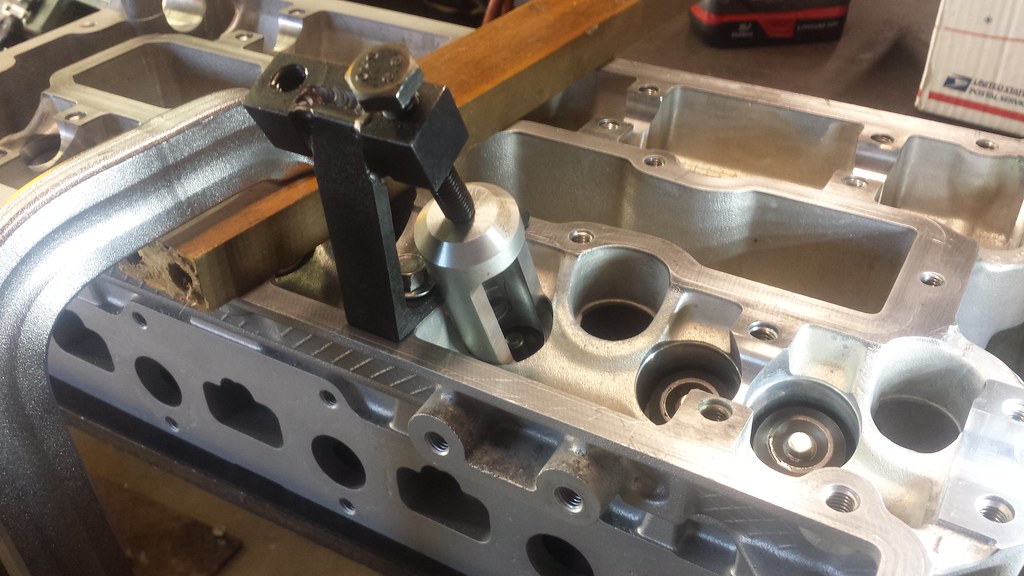

It hurt my hand to slam the lifters like in the video, so I made a tool to knock them apart

Re: Rebuilding hydraulic lifters

Posted: Sun Jan 15, 2017 4:41 pm

by Jon1

Re: Rebuilding hydraulic lifters

Posted: Mon Jan 16, 2017 12:34 am

by squaab99t

Jon1 wrote:It hurt my hand to slam the lifters like in the video, so I made a tool to knock them apart

I remember my hand smarting pretty good on that maneuver. Good looking tooling. Tools, separates us from animals...

Re: Rebuilding hydraulic lifters

Posted: Mon Jan 16, 2017 12:00 pm

by gmreider

Jon, Interesting Stuff. I am going out and start banging my lifters on a board.

I like your tooling also. When I get some time I will send photos of my tooling for head work for your review. I do some things a bit different, but you may find them useful.

Re: Rebuilding hydraulic lifters

Posted: Wed Jan 18, 2017 8:19 am

by DeLorean

Gary has head work down to a production line science. I think it took us about 1/2 an hour to do the valve seals & Volvo 240 valve spring upgrade in my T5 head for the hillclimb car.

Re: Rebuilding hydraulic lifters

Posted: Thu Jan 19, 2017 9:30 am

by Jon1

I am almost embarrassed to say, these are the first heads that I have ever taken apart and reassembled. I have never had a need to do so before. I look forward to seeing Gary's procedure.

Re: Rebuilding hydraulic lifters

Posted: Tue Mar 21, 2017 8:50 am

by Nate

How hard did you have to "slam" the lifter? I copied your tool design and slammed the lifter against a piece of pine & just ended up nicking the lifter's edge. Seems counter-intuitive to hit the lifter to pop the piston out when it should pull out. I don't know how to grab on to it without mangling up the piston though.

Re: Rebuilding hydraulic lifters

Posted: Tue Mar 21, 2017 11:45 am

by Jon1

I made the tool so the lifter is a tight fit, so it won't fall out. Some of them came out with only one or two hits, a few took three or more hits. It takes quite a lot of force to get them to come out.

Re: Rebuilding hydraulic lifters

Posted: Tue Mar 21, 2017 4:16 pm

by Geoff

Jon, thanks for sharing this. It's pretty cool to see that they can be popped apart and cleaned.

We have one of these at work, maybe this would get them apart?

https://www.youtube.com/watch?v=kDs6jQmNEdM

Re: Rebuilding hydraulic lifters

Posted: Thu Mar 23, 2017 10:31 pm

by gmreider

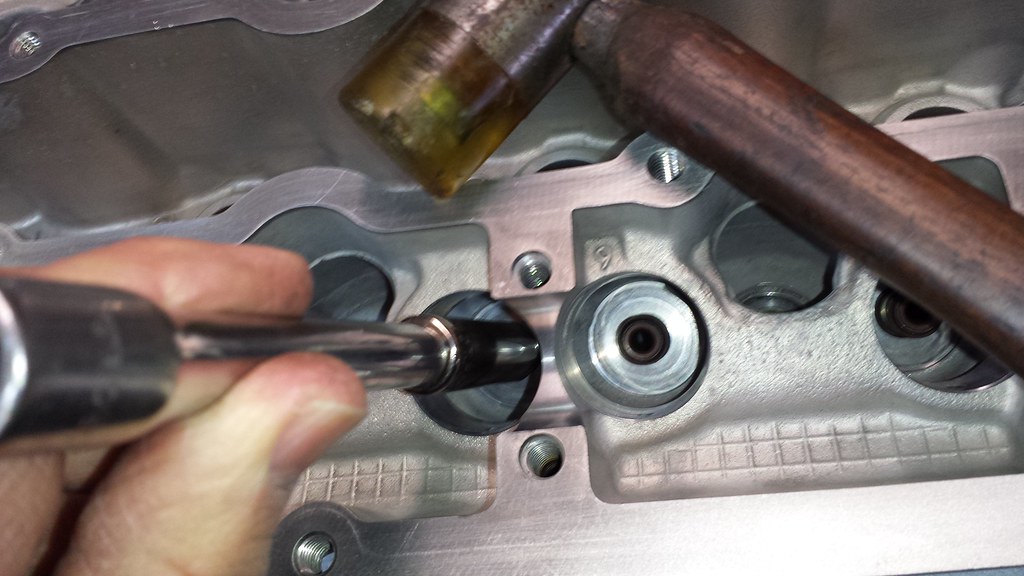

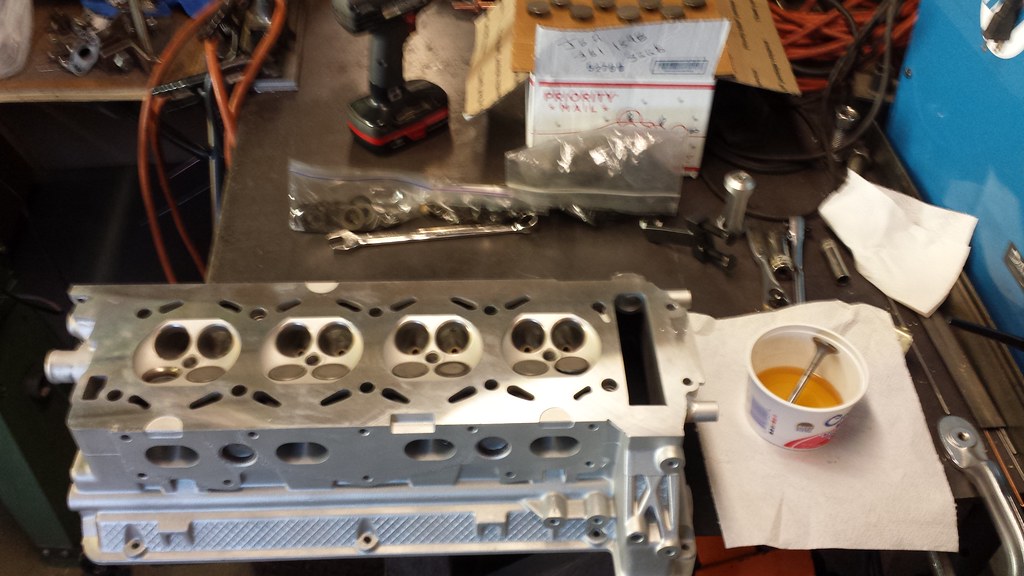

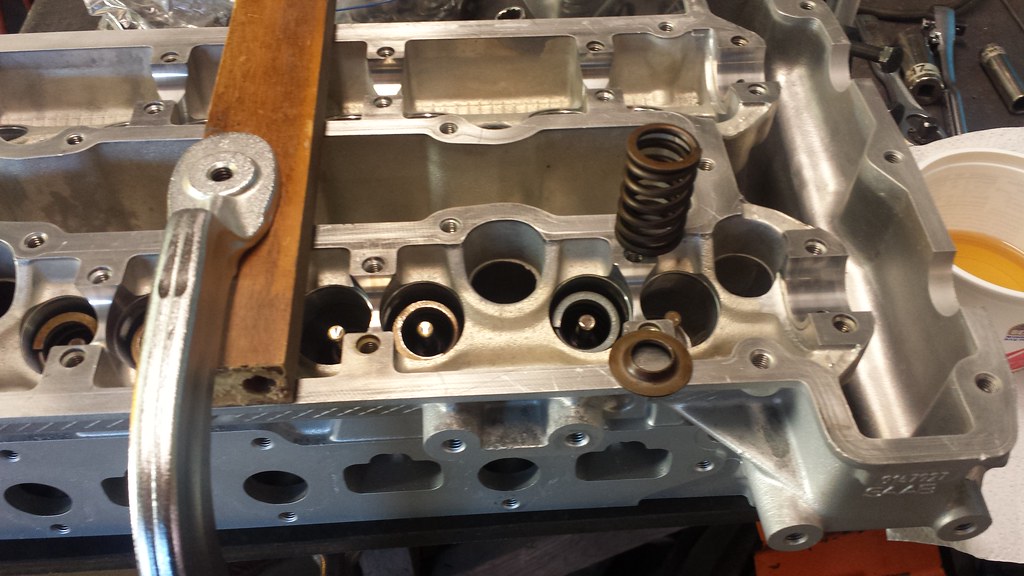

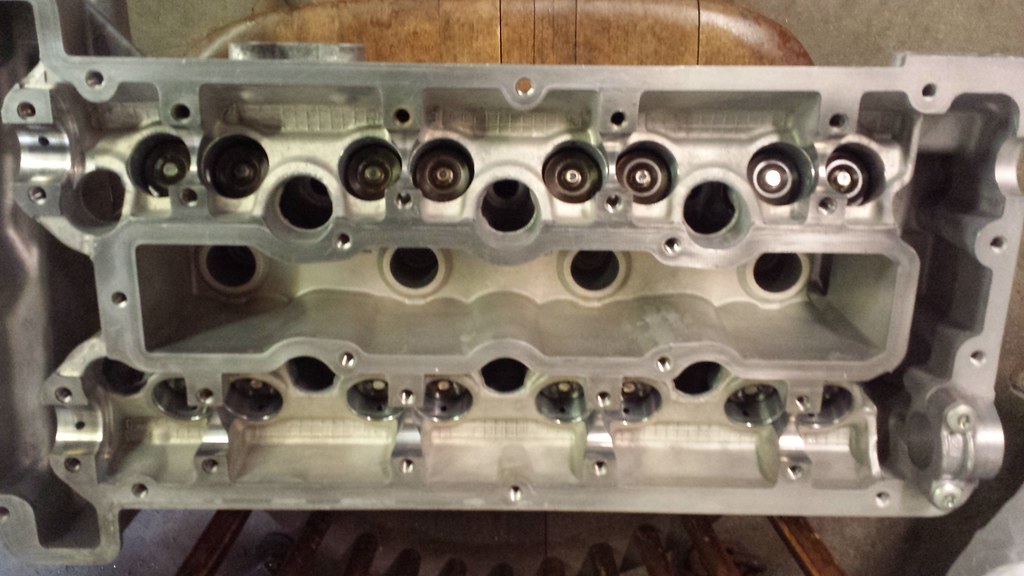

OK Jon, here are my methods and tricks for head work.

(1) I use a head holder stand as shown in photo, It allows me to swivel it all around and work from all sides and stand comfortably.

(2) I use a clamp type spring compressor with an old factory tool to compress the springs. Note I use a blue sleeve to protect the lifter bore as I work on each cylinder. Once you get used to the C clamp setup, it is quick.

(3) I show a home made valve seal installer. I oil up the vale stem and insert valve, oil the seal and slide it over the valve and then tap the seal in place. So the tool is guided by the valve stem.

(4) then I toss the spring and retainer in and use the C clamp. look at the neat magnetic keeper holder in the photos. I enter the tool straight down thru the top of the spring compressor and give a squeeze on the keeper tool to set the keeper and release the C clamp with the other hand. the C clamp tool is made to release with one hand and the keeper tool just slide off and the job is done.

I am sure there are small details that I have not mentioned, but this will get you thinking. I can strip a head for valve work in 1/2 hour or maybe less, and can lap in valves, install valves and seals, springs and lifters and cams in an hour and 1/2 or maybe less.

I notice that I show a pliers that is for removing the seals. It works great and is a available. The keeper tool , I have had for years , but I see similar versions for sale. These gadgets make the job nicer and quicker.

Next up when I get time is my take on installing the Quaife in C900 and the methods that I have used. That is when I get time. Enjoy>

Re: Rebuilding hydraulic lifters

Posted: Fri Mar 24, 2017 5:28 am

by Jon1

Gary, that is a nice set-up! Thanks for sharing.